Chrome damage in industrial settings arises from handling, chemicals, and collisions, leading to scratches, dents, and corrosion. Specialized techniques like precision grinding, polishing, and high-quality coatings are required for effective chrome repair restoration. These tailored solutions ensure longevity and enhanced appearance, crucial for durable commercial applications. Regular maintenance, including cleaning and inspections, extends the lifespan of restored chrome surfaces.

In industrial and commercial environments, chrome surfaces are integral for their aesthetic appeal and functional properties. However, these surfaces are prone to damage due to constant exposure to harsh chemicals, abrasives, and wear-and-tear. This article explores comprehensive solutions for chrome repair and restoration, focusing on understanding various forms of chrome damage in demanding settings. We delve into effective restoration techniques tailored for commercial applications, ensuring longevity and optimal maintenance practices for restored chrome surfaces.

- Understanding Chrome Damage in Industrial Settings

- Restoration Techniques for Commercial Chromed Surfaces

- Longevity and Maintenance After Chrome Repair

Understanding Chrome Damage in Industrial Settings

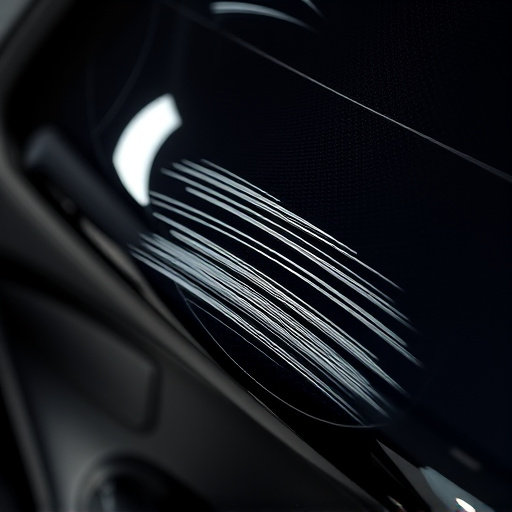

In industrial settings, chrome damage can stem from various factors, including frequent handling, exposure to harsh chemicals, and accidental collisions. Understanding the specific causes is crucial for effective chrome repair restoration. For instance, heavy machinery and equipment can lead to scratches, dents, or even pitting on chrome surfaces over time. Chemical spills and fumes can also cause corrosion, undermining the integrity of the chrome finish.

Moreover, in high-traffic areas like manufacturing plants or warehouses, accidental collisions with vehicles, pallets, or other objects are common, resulting in significant chrome damage. Unlike auto repair services for personal vehicles, industrial chrome repair restoration requires specialized techniques and materials to ensure durability and longevity. A competent car body restoration expert understands these challenges and employs tailored solutions, such as precision grinding, polishing, and high-quality coatings, to restore the chrome to its original condition or even enhance it with modern finishes.

Restoration Techniques for Commercial Chromed Surfaces

Restoring chromed surfaces in commercial settings involves a meticulous process tailored to meet specific needs. The primary techniques include chemical polishing and buffing, which are effective for removing scratches and pitting that can diminish the luster and aesthetic appeal of chrome finishes. These methods are especially crucial in industrial applications where durability and longevity are paramount, such as in manufacturing equipment or architectural fixtures.

Professional restoration experts often employ specialized tools and compounds to achieve a seamless blend with minimal disruption to the overall surface. Similar to car bodywork and paint services, precision is key. For commercial chromed surfaces, this means addressing unique challenges like environmental exposure, frequent use, and high-traffic areas. By employing advanced chrome repair restoration techniques, these issues can be mitigated, ensuring that the restored surfaces not only look as good as new but also withstand the rigors of commercial environments.

Longevity and Maintenance After Chrome Repair

After successful chrome repair restoration for industrial or commercial purposes, ensuring longevity and proper maintenance becomes paramount. Chrome, known for its durability, can withstand harsh conditions but requires regular upkeep to prevent damage from corrosive elements, extreme temperatures, and wear and tear. A well-maintained chrome surface can last for years, preserving the aesthetic appeal and functionality of various components in industrial settings.

Regular cleaning and inspection are key steps in maintaining restored chrome. Using appropriate cleaners and avoiding abrasive materials helps prevent scratches and other forms of damage. Inspections should be conducted at scheduled intervals to identify any signs of wear or potential issues early on. For instance, checking for loose or damaged parts, pitting, or corrosion can help facilitate prompt repair, averting more significant problems that could require extensive auto glass replacement or tire services in the case of a fender bender.

Chrome repair and restoration are essential processes for maintaining industrial and commercial applications. By understanding the types of chrome damage that can occur in demanding environments, utilizing effective restoration techniques, and implementing proper maintenance strategies, businesses can extend the lifespan of their chromed surfaces. These steps contribute to a smoother, more efficient operation and help reduce costs associated with frequent replacements. Thus, investing in chrome repair restoration is a smart move for any company seeking long-lasting, high-quality results.